Does Marble absorb water?

Nature of Marble

The word marble derives from the ancient Greek mármaron or mármaros, meaning ‘shining stone’, itself derived from the verb marmàir, meaning ‘to shine, to sparkle’.

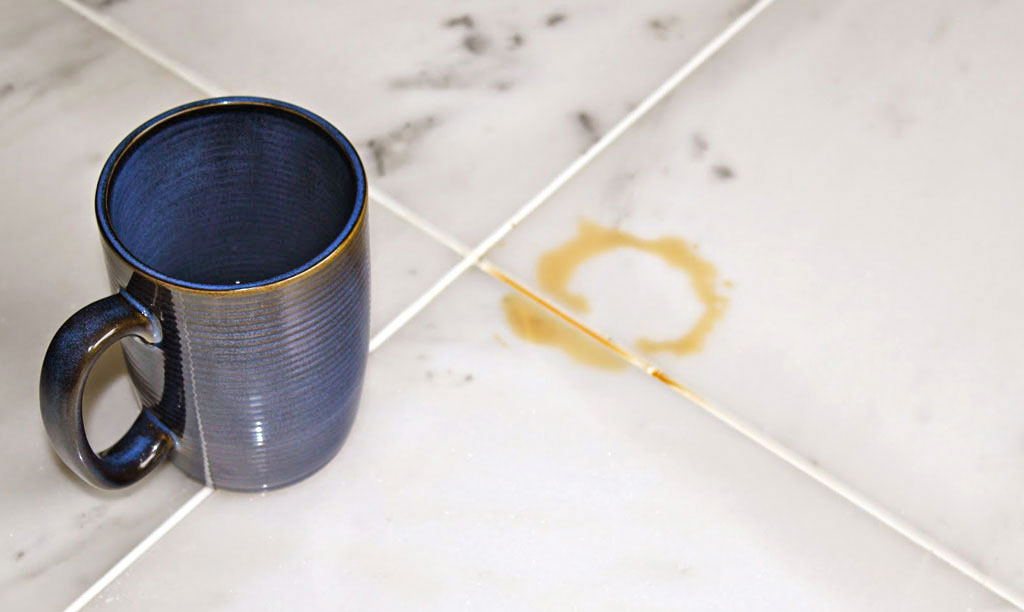

As a type of stone which is formed from sedimentary materials such as limestone and dolomite, marble is particularly porous and, therefore, it absorbs water. It is important to assess beforehand where to use it and what protection to provide it with, to avoid stains. Regular cleaning is also useful to keep surfaces nice and shiny: all you need is a damp cloth, neutral soap, warm water and chamois leather to polish at the end.

In the case of granite and quartz, the absorption coefficient is lower than that of marble. This implies that these materials are less delicate.

In the case of granite and quartz, the absorption coefficient is lower than that of marble. This implies that these materials are less delicate.

The combined action of temperature and pressure generates recrystallisation of the stone, resulting in a mosaic of calcium carbonate crystals and dolomite.

Marble’s hues and veining depend on the impurities within it during the metamorphic process. Mineral impurities such as clay, silt, sand and iron oxide are displaced and recrystallised due to pressure and heat.

White marbles are usually the result of the metamorphosis of limestones completely free of impurities.

Surface processing techniques

Polishing

There are three available systems to polish slabs: manettone, belt, and chemical tecnique The manettone technique is a very simple and versatile manual system, which ensures high quality, but allows smaller quantities of slabs to be processed. The belt technique is a much more efficient process, which ensures high productivity and, in many cases, also quality. The chemical technique, which uses certain acids, allows an extremely homogeneous finish.

Flaming

Together with sanding and polishing, it is among the most-commonly finishes in the market. It is carried out using a flame fuelled by oxygen and propane, which causes a thermal shock that gives the surface layer a rough appearance. This technique is mainly used outdoors, both for aesthetic reasons and because it is non-slip.

Bush-hammering

Widely used in the past to give a ‘sculptural effect’ to the product, this finishing technique sculpts the surface using rollers and pneumatic hammers.

Sandblasting

his consists of a sanding technique using a combination of a water jet and sand, all delivered through nozzles arranged on a series of rollers.

Brushing

Also known as antiquing, this is a technique that uses special brushes to give the surface a worn effect.

Acid-etching

This technique uses special acids, which concentrate in the softer areas of the material, creating an antique, rough, and irregular finish.